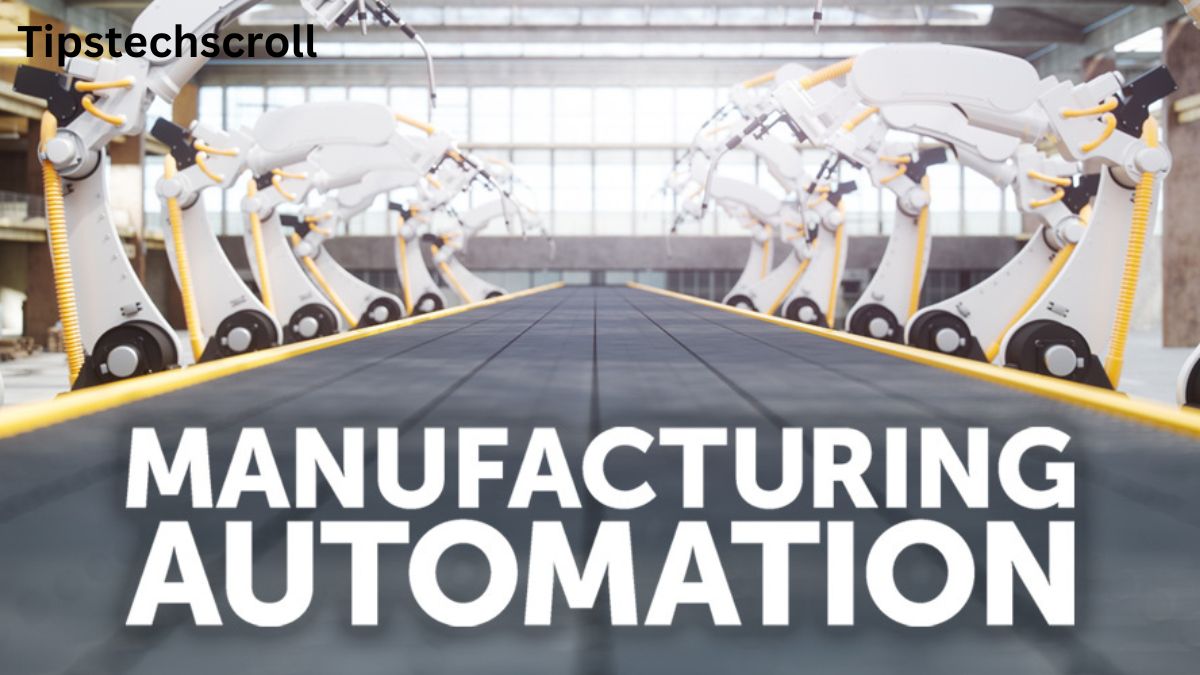

Automation Manufacturing, Manufacturing automation is one of the most important technologies in the ever-evolving landscape of manufacturing. This is an integration of technology and machinery in the production processes. It promises an increase in efficiency and a significant shift in humans’ role on the factory floor.

Automation Manufacturing industries showed remarkable efficiency in producing goods. However, this technology also has some challenges. It needs a skilled workforce to manage this powerful new technology. prompting important discussions about job displacement requires skilled force.

In this article, you will explore the information about automation manufacturing companies. You will also get information about manufacturing automation systems and their types.

What is automation in manufacturing or production?

It is the technology to take over tasks that were previously done by humans. This can involve using robots, computer-controlled machines, and software to perform a wide range of tasks. It can perform many tasks from assembling products to packaging finished goods.

Due to some factors, Automation has become important in manufacturing. First of all, it reduces costs and improves the efficiency to compete in the global marketplace. Automation helps in achieving those goals by reducing labor costs. But besides all of these, its setup has a high initial cost to get a start.

Whatever, many parts of the world are facing labor shortages, automation can address these challenges by taking over these tasks. In simple words, advancements in robotics, artificial intelligence, and other technologies are making it possible to automate more and more tasks in manufacturing.

Types of Automation:

In automation, robots can assemble products alongside humans with remarkable speed and accuracy. Many types of automation can perform different tasks. Get ready to read about the different types of automation that are revolutionizing how things are made.

Fixed Automation:

Fixed automation is also known as hard automation. It is just like a workhorse that has high-volume production. Highly specialized machines that produce the same product continuously when fixed automation is in action. The following are the key features of a fixed automation machine.

- Production of a Single Product: Fixed automation systems are designed to produce the same product. It is built to produce a specific product or a very limited range of similar products.

- Pre-programmed Arrangement: The entire production process is fixed by the physical arrangement of the machines. It includes cams, gears, and wiring. This is a very complex automated technology that can’t be easily changed.

- High Production Speed: Fixed automation is excellent at producing large quantities of identical products. It performs tasks very quickly and efficiently.

- Examples: Assembly lines in the auto industry, bottling lines for beverages, and chemical processing plants are examples of fixed automation.

Pros:

- Lowers production costs per unit.

- Gives high output.

- Decrease labor needs.

- Increases production speed and efficiency.

- Maintains consistent product quality.

Cons:

- High initial investment.

- Less flexible.

- Switching to a different product requires significant modifications or even a complete rebuild.

- Limited job innovation.

Programmable Automation

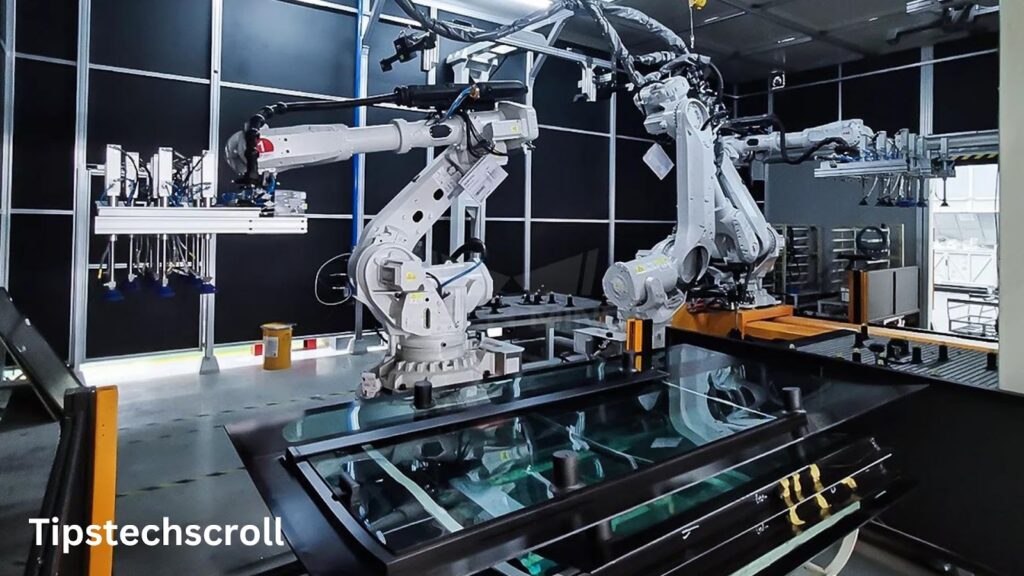

Fixed automation is a spectacle of engineering that produces identical products at amazing speeds. On the other hand, Programmable Automation helps where production needs are more dynamic. If the product design is subject to frequent changes then this type of automation is best. Programmable automation offers manufacturers much more flexibility without sacrificing efficiency. Here are some key features of Programmable Automation:

- Adjustable to Various Products: Programmable automation uses computer-controlled machines that can be reprogrammed. It can handle different tasks or produce a variety of similar products.

- Software Control: Its software can be controlled and changed at any time. You can instruct the machines on new assembly sequences by changing their program.

- Production in batches: Sometimes you need to switch between different products periodically where it helps potentially. Programmable automation is ideal for medium-volume production.

- Examples: Industrial robots, CNC machines (computer numerical control), and programmable logic controllers (PLCs) are examples of programmable automation.

Pros:

- More flexible than fixed automation

- Lower initial investment

- More efficient for batch production.

Cons:

- Slower production rates

- Requires skilled workers to program and operate the machines.

Process Automation:

Process automation is a more general term that contains both fixed and programmable automation. It is the automation of entire manufacturing processes with the help of Artificial Intelligence. The following are the key features of Process Automation.

- Automating Entire Process: With the help of Process Automation, an industry can perform a series of interconnected tasks. Assembling a car or packaging goods can easily be done in Process Automation.

- Data-Driven Conclusions: In this technology, real-time data collected from sensors and machines is used to optimize production.

- Software Arrangement: This software acts as a coordinator between different machines and systems. It maintains the flow of materials, information, and tasks between them.

- Examples: Automated order fulfillment systems, just-in-time (JIT) inventory management, and automated quality control processes are all examples of process automation.

Pros:

- Increased overall efficiency.

- Improved product quality.

- Reduced production costs.

- Enhanced decision-making through data-driven insights.

Cons:

- High initial investment in software, hardware integration, and potential infrastructure changes.

- Complexity in setting up systems.

- Need for skilled IT professionals to manage and maintain.

FAQs

What is automation in the IT industry?

IT automation is the process of creating software and systems to replace repeatable processes and reduce manual intervention. It accelerates the delivery of IT infrastructure and applications by automating manual processes that previously required a human touch.

Is manufacturing automation?

Automation in manufacturing refers to using technology and machines to perform specific tasks without the need for humans to intervene. The goal of automation is to increase efficiency, productivity, and accuracy in the production process, reducing manual labor and minimizing the risk of human error.

What is automation and engineering technology?

As a graduate of the Automation Engineering Technology program, you’ll be ready to work with integrated machine systems that involve industrial automation, robotics, mechanics, computers, industrial communications, and/or electronics technology.

Which one is better industrial automation or embedded systems?

Embedded systems typically deal with the interaction between electronics and firmware, while industrial automation focuses on the control logic of a system or process.

How to get Automation Manufacturing?

Automation in manufacturing is achieved by using programmable devices, systems, and tools such as artificial intelligence, robots, and computer-controlled machines. Automation is most frequently used to automate repetitive or dangerous tasks, which frees up human labor to focus on more highly skilled tasks.

Conclusion:

The automation revolution in manufacturing is here, and it’s not just about robots replacing humans. It’s about a smarter, more efficient way to make things. From the high-speed precision of fixed automation to the adaptable nature of programmable systems and the interconnected workflows of process automation, there’s a type of automation to suit a variety of manufacturing needs.

While concerns about job displacement are valid, automation is also creating new opportunities. The need for skilled workers to design, program, maintain, and manage these automated systems is stronger than ever. As automation continues to evolve with artificial intelligence and machine learning, the future of manufacturing promises even greater efficiency, flexibility, and innovation.

Greetings! I’m jordan, the proud Owner of Tipstechscroll. With 7 years of experience in SEO, I’m passionate about aiding businesses in their online growth journey. My expertise lies in crafting content that resonates with search engines while ensuring visibility to the intended audience. By staying abreast of the ever-evolving SEO landscape, I alleviate the burden for my clients, ensuring their online presence remains optimized. My goal is to impart my knowledge and empower others to thrive in the digital realm.